Premium Aluminium Extrusions, Sheets, and Bespoke Metalwork

Delivered UK Mainland

To Help You Decide on the Most Suitable Products, We have 400 + Free Samples Available for Immediate Dispatch.

Order Aluminium Extrusions & Sheets Online

Fast, Simple, Reliable

Ordering aluminium stock online is quick and easy with Gooding Aluminium. Shop a wide range of aluminium and aluminium alloy extrusions and sheet — available for fast dispatch.

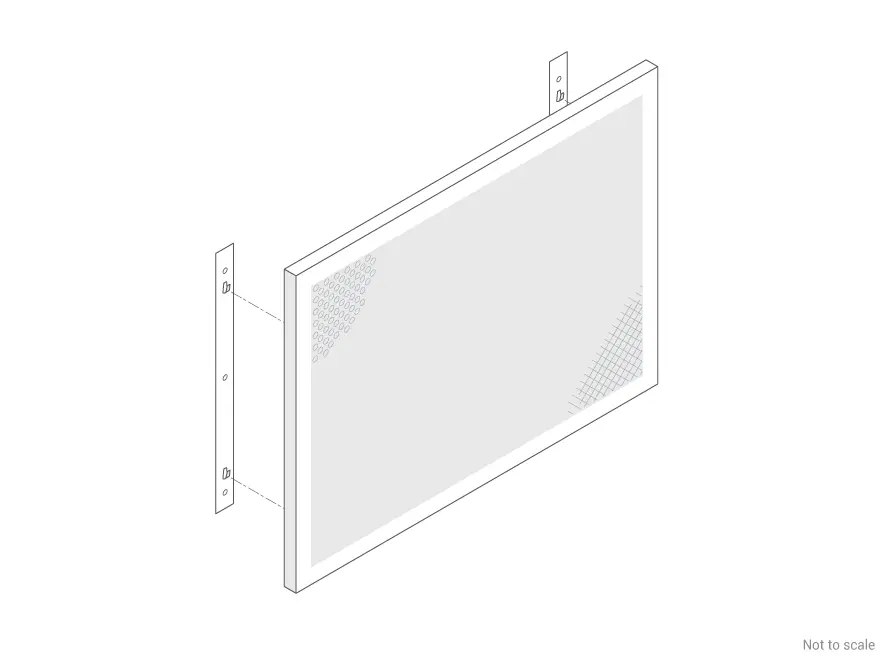

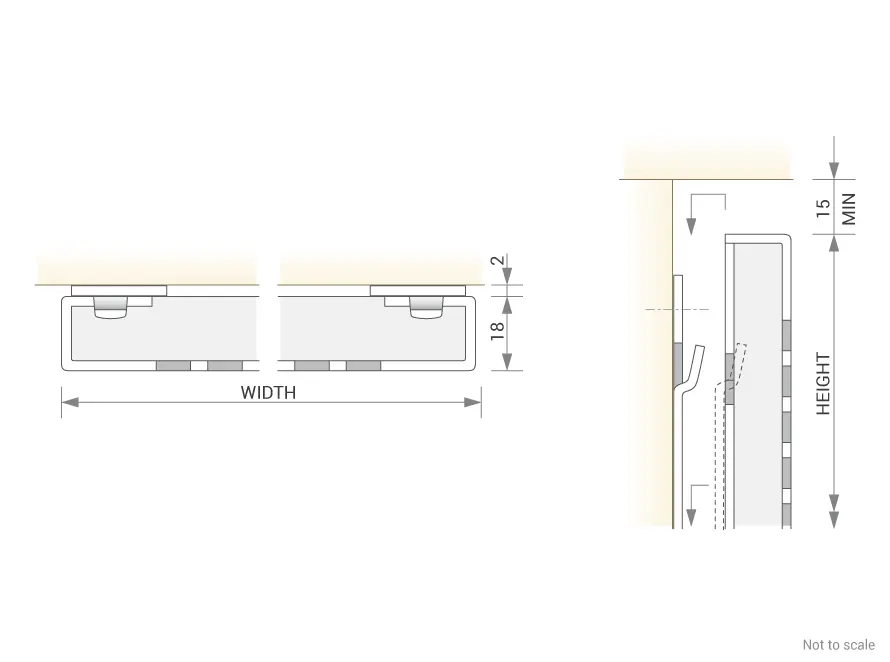

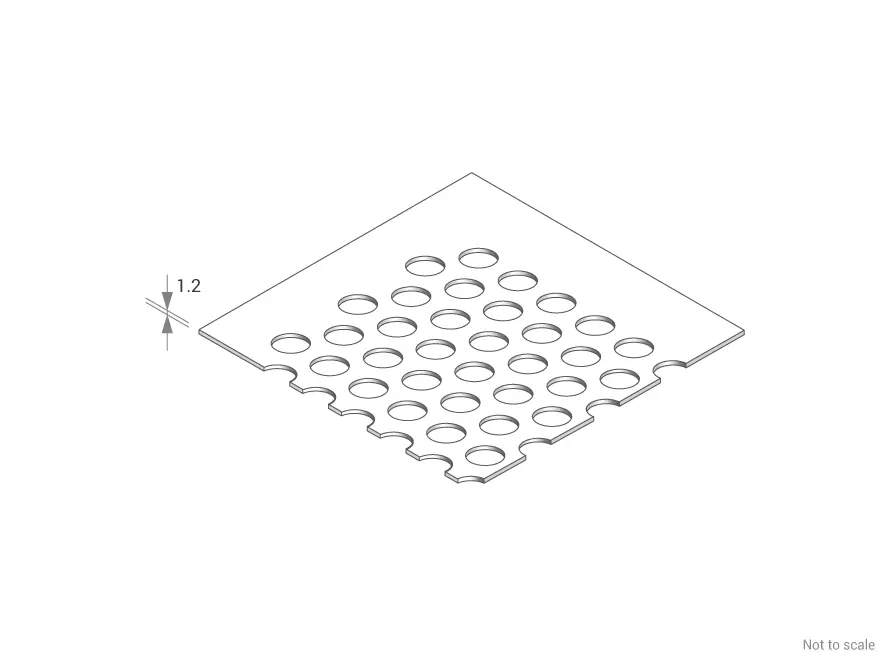

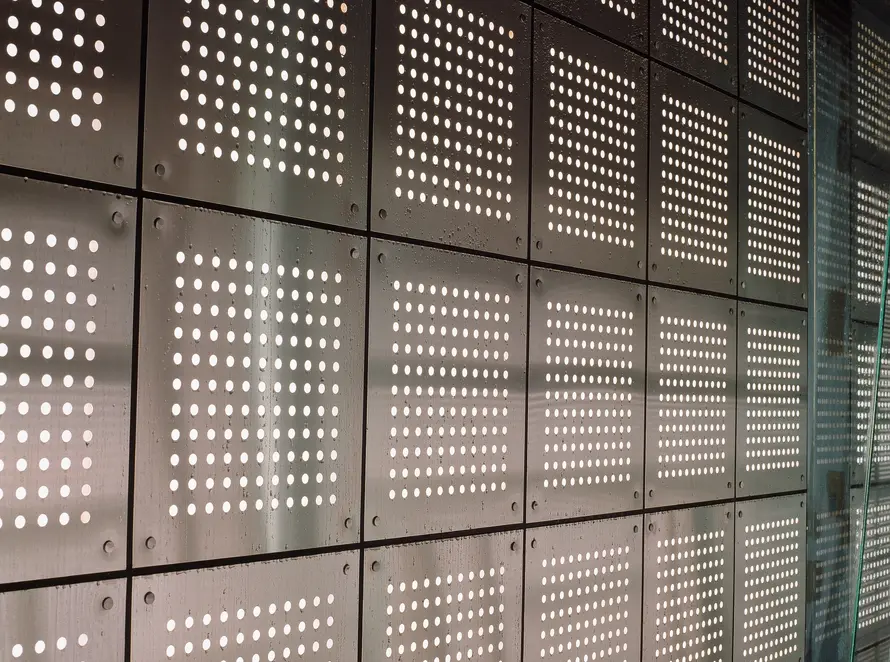

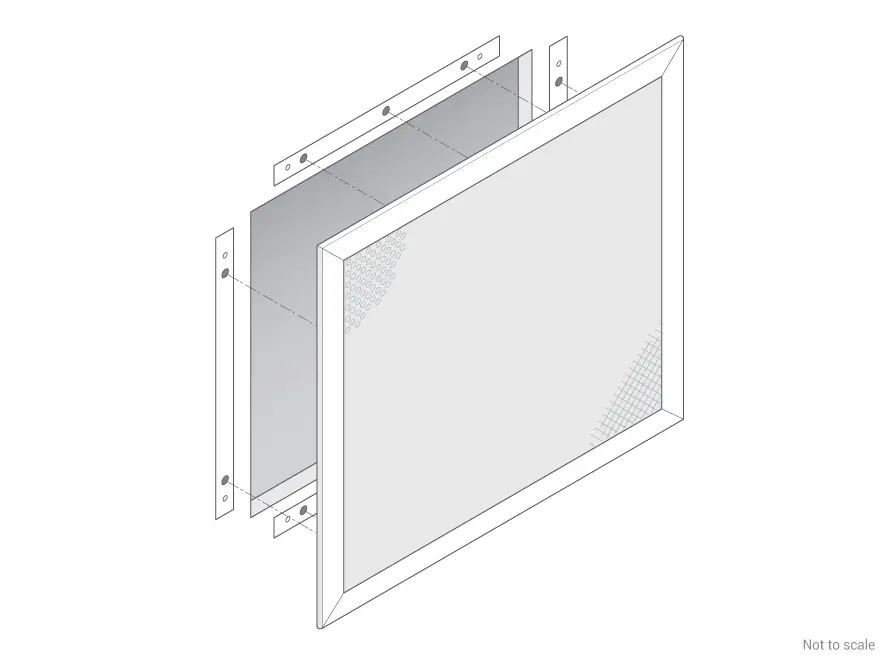

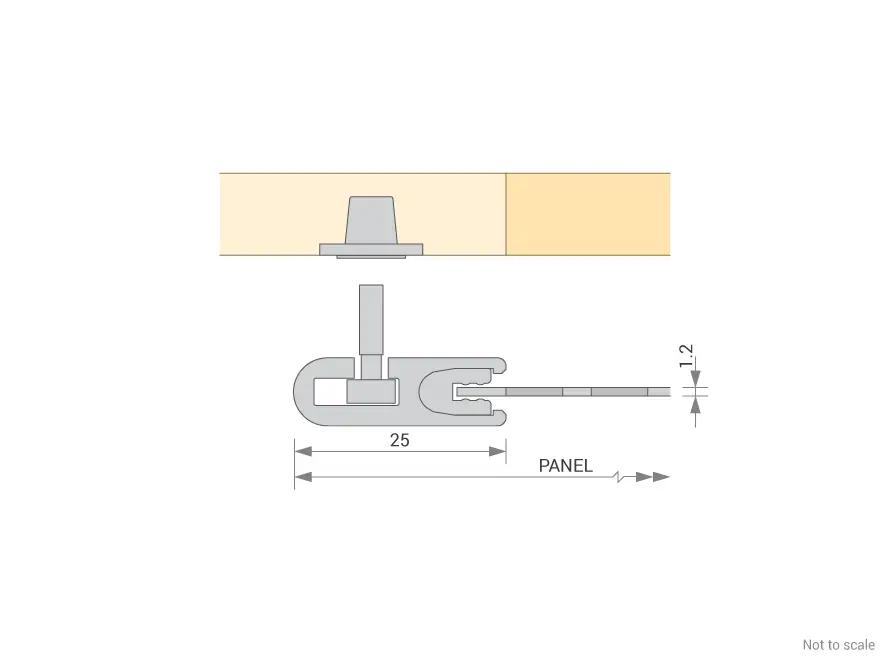

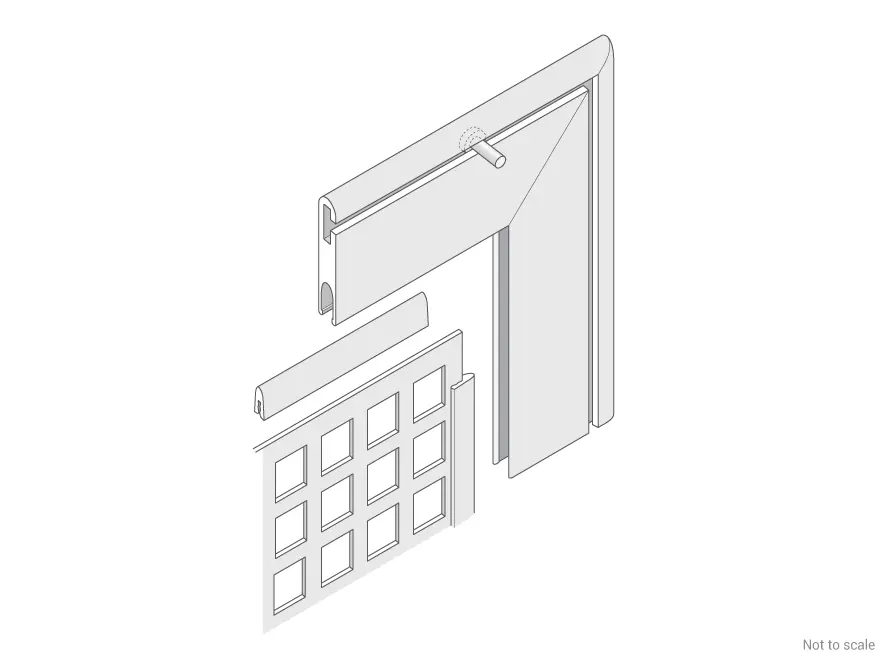

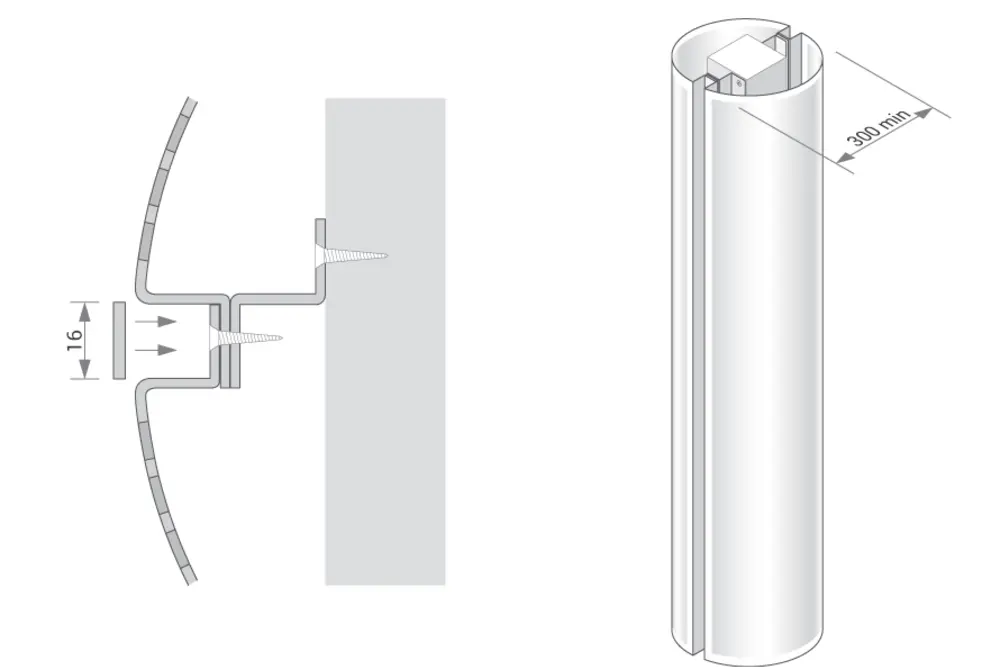

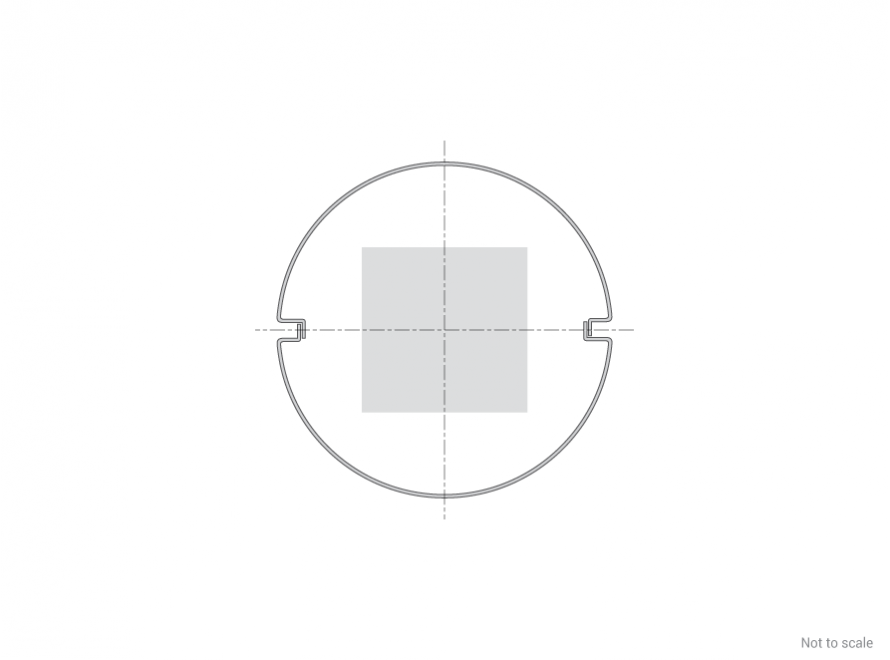

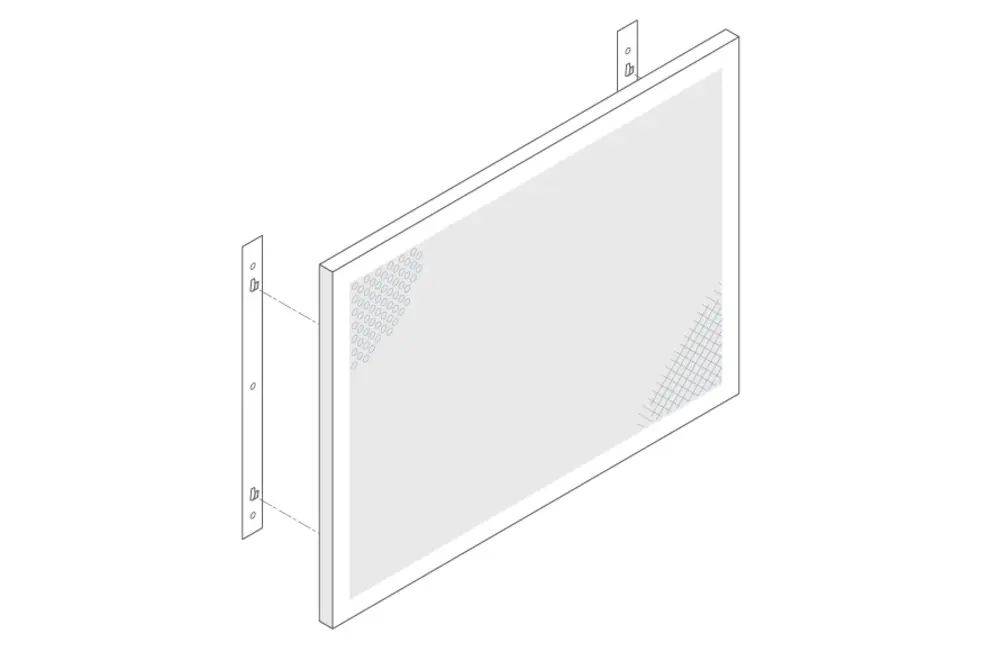

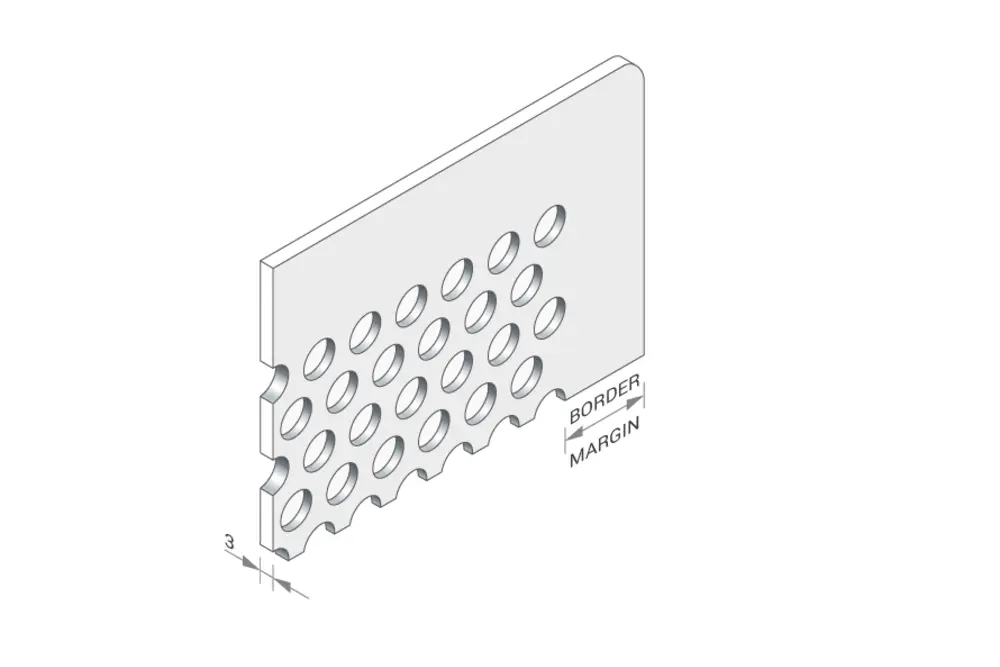

From glazing channels, trims, stair nosings and fixings to everyday angles, channels and sections, you’ll find the right profile for your project. For added impact or performance, explore our perforated and textured sheets in a range of finishes.

Discover the Gooding Aluminium range

Browse our brochures to explore our aluminium products and perforated sheet options, with details on standard sizes, patterns, and processing. Built to help you specify with confidence.

Our 5 Star Service: Made-to-Measure Aluminium

Fast Turnaround - Fabricated Aluminium Products

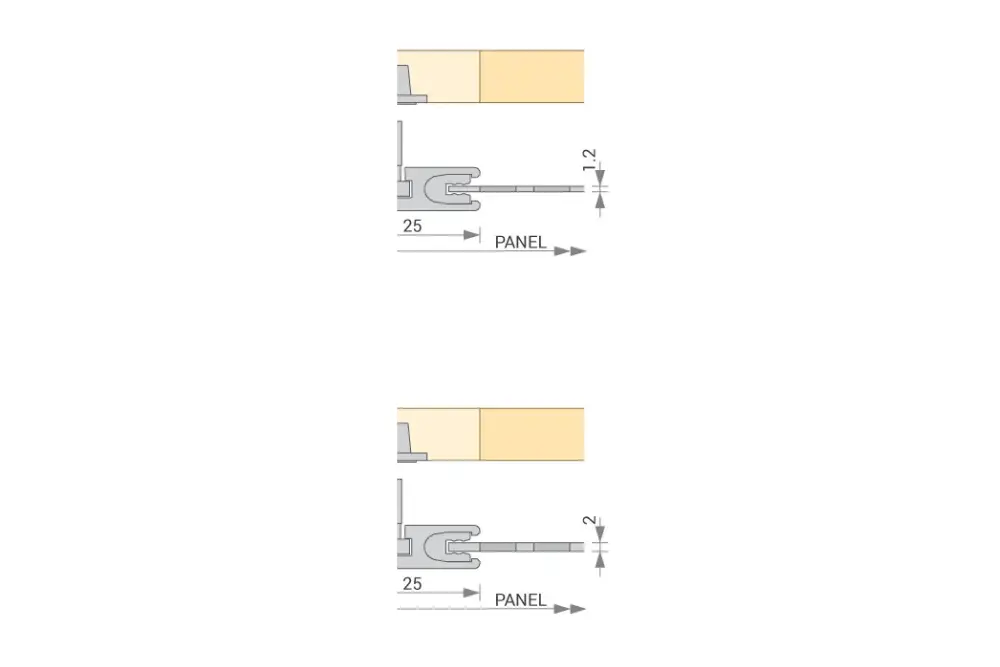

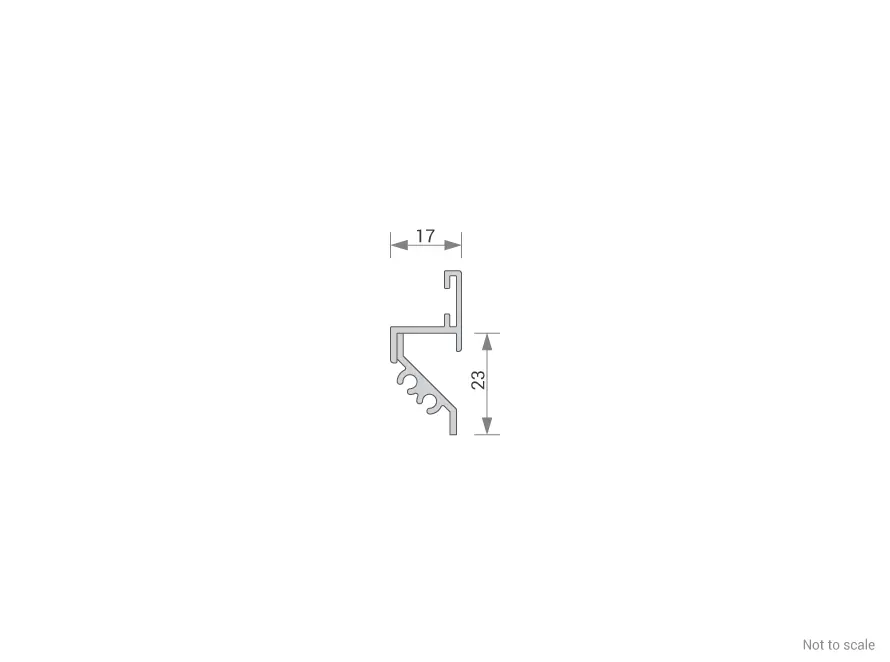

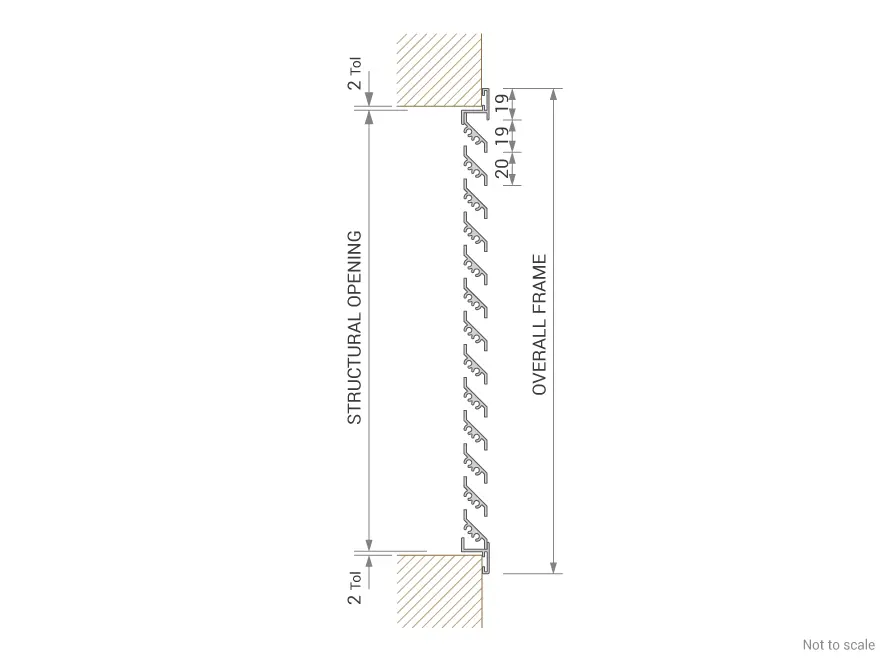

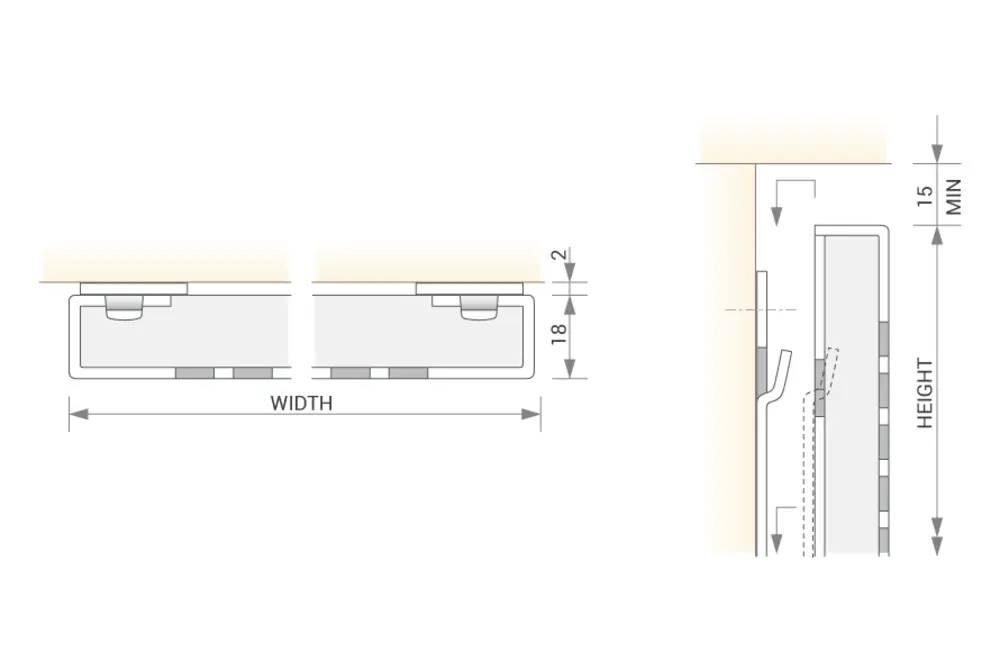

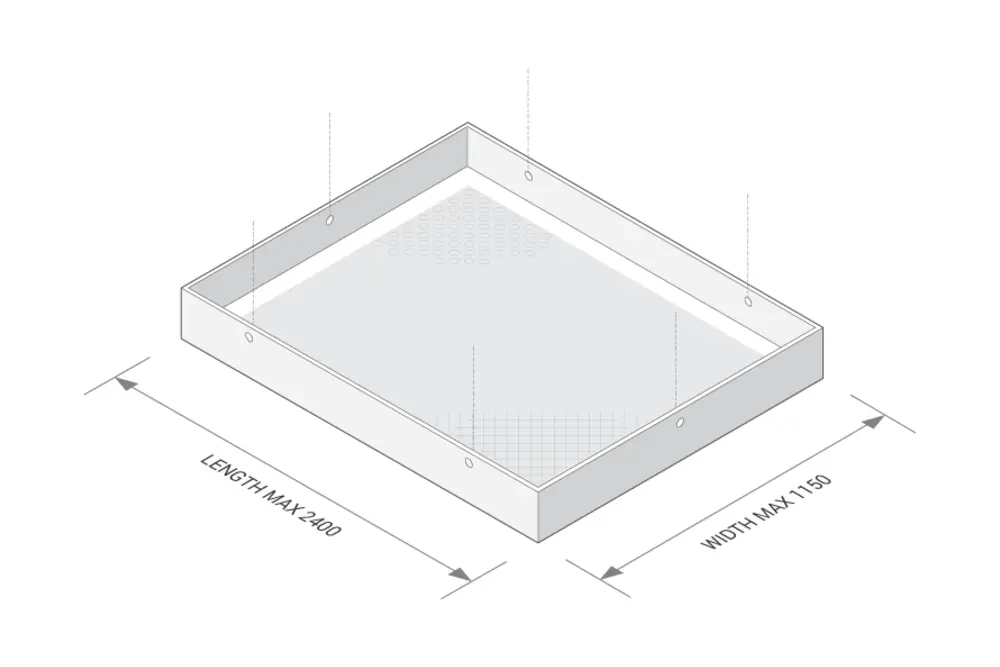

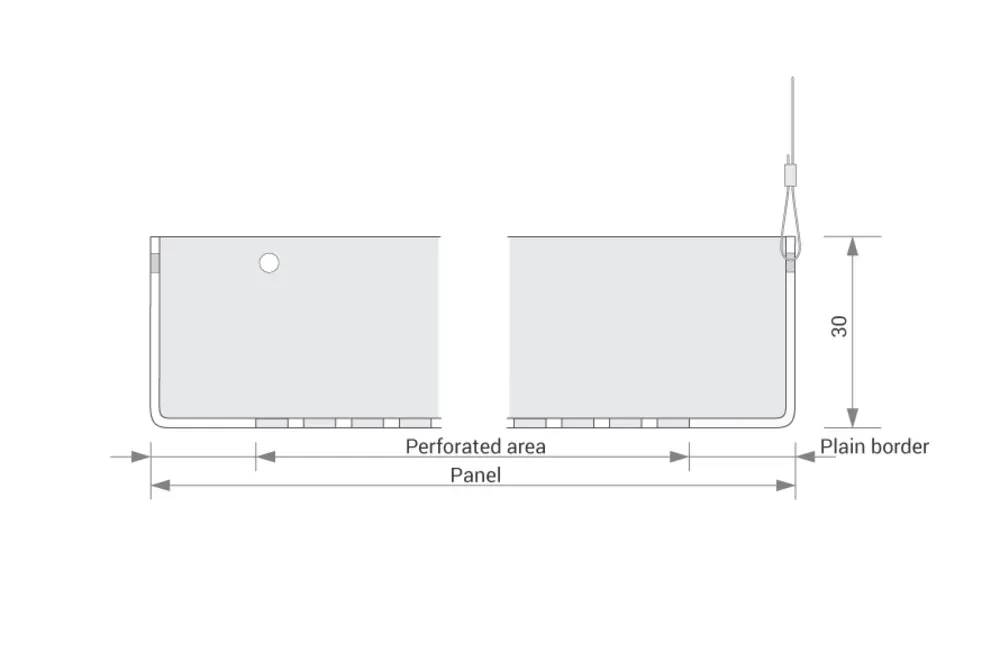

GA’s Five Star Fabricating Service delivers aluminium-only expertise with precision perforating and fabrication. Get custom-sized perforated panels (including plain borders), light-gauge 1–3mm fabrication, and polyester powder coating — with clear tolerances, bespoke detailing, and fast turnarounds. Budget-friendly packages available.

Trusted by Customers Across the UK

Real feedback matters. Here are the latest Google reviews from customers who rely on Gooding Aluminium for quality aluminium stock, made-to-measure fabrication, and dependable service — from first enquiry through to delivery.

Posted onTrustindex verifies that the original source of the review is Google. Gooding Aluminium were very helpful and competitive. The PPC trims we required were delivered on time and were of good quality. Our client was very happy with the final result, thankyou.

Owner's reply

Hello Andrew, thanks for your helpful review. Much appreciated!Posted onTrustindex verifies that the original source of the review is Google. Fast service with a very good range of stock

Owner's reply

Thank you so much for taking the time to write a review. We’re pleased we could help.Posted onTrustindex verifies that the original source of the review is Google. Attentive and timely. Good products as described. Highly recommend

Owner's reply

Many thanks for your positive feedback. Much appreciated.Posted onTrustindex verifies that the original source of the review is Google. They have a specific product and a general level of service that is unrivalled in our industry

Owner's reply

Hello Alex, thanks for your helpful feedback.Posted onTrustindex verifies that the original source of the review is Google. With their user-friendly and informative website, I easily ordered four samples of perforated aluminium. The quality overall was remarkable, from the material to the customer service via email and phone. I got exactly what I was looking for, thank you Gooding Aluminium!

Owner's reply

Thanks for taking the time to write a review and for the positive feedback.Posted onTrustindex verifies that the original source of the review is Google. Great service. Incredibly helpful and informative.

Owner's reply

Thanks James. We really appreciate your kind feedback.Posted onTrustindex verifies that the original source of the review is Google. We have been using Gooding Aluminium for years, always spot on with service. Very professional & have never let me down. Also developed a partition glazing system that we use all the time.

Owner's reply

Hello Mark, thanks for the positive review. It's great to hear your feedback. Thanks again.Posted onTrustindex verifies that the original source of the review is Google. Great people to do business with, quality product and service.

Owner's reply

Hello Paul, Thank you so much for taking the time to give us this positive feedback. It's really appreciated.Posted onTrustindex verifies that the original source of the review is Google. Great service and great products.

Owner's reply

Hi James, thanks for taking the time to give us a review. We're pleased you're happy with our service!Verified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more

Quality Assurance

Total quality service — from first spec to final performance.

For GA, quality isn’t just the product. It’s the full experience: support at pre-specification, precision through fabrication, and reliable performance once installed.

We continuously gather feedback from specifiers and end users to refine how we work and keep standards consistently high.

Backed by BS EN ISO 9001:2015, our aluminium fabrication and service processes are built to deliver one thing every time: a complete, confident result.

The Gooding Aluminium YouTube Channel

Product demos, fabrication insight, and real-world aluminium applications

Explore the Gooding Aluminium YouTube channel for practical videos covering our aluminium extrusions, sheets, perforated patterns, and fabrication capabilities. See products up close, learn how different options perform, and get ideas for your next project — then subscribe to stay up to date with new releases and project inspiration.

Explore GA YouTube Videos

0:16

0:16

0:16

0:16

0:16

0:16

Why Choose Gooding Aluminium?

At Gooding Aluminium, we combine over four decades of industry expertise with state-of-the-art processing capabilities to deliver high-quality, precision-engineered solutions. Whether you are looking for standard stock items or complex bespoke fabrications, our commitment to exceptional service and rapid delivery ensures your project is supported every step of the way.